Capabilities

You need packaging that’s secure, affordable, safe to use, and showcases the very best of your products and your brand.

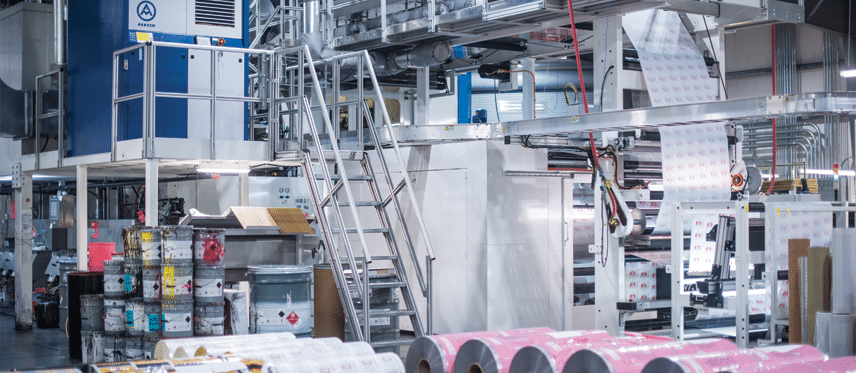

We offer customized flexible packaging solutions to fit all your needs. From printing and laminating to coating, slitting, pouching, and bag making, we’ve got everything you need. Our top-of-the-line technologies allow us to offer a wide variety of configurations and options to get the exact packaging you need for your products.

What Sets Us Apart?

Committed to Quality

We invest in state of the art technologies to provide you with top quality packaging solutions for all your needs.

Flexible to Fit Your Needs

We produce world class quality at a reasonable price, and in reasonable volumes.

FDA Approved Materials

All food packaging is made in compliance with FDA regulations and are guaranteed free from harmful substances.

Outstanding Customer Service

As a family owned business, we believe in the power of building lasting business relationships. Your satisfaction is our goal!

Our Processes

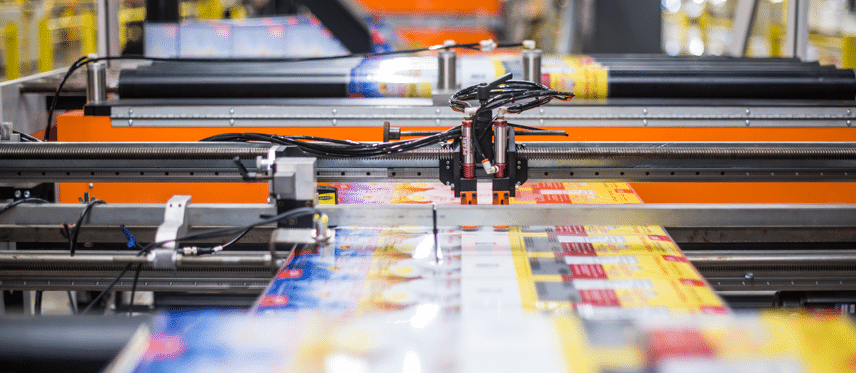

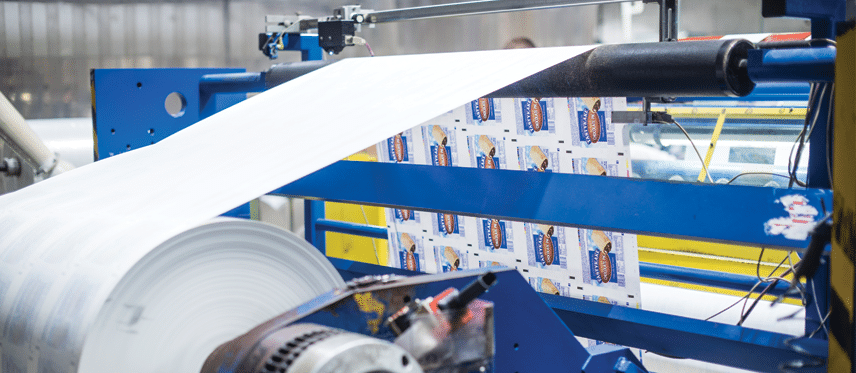

Printing

Our top of the line 10-color PCMC flexographic printing presses and X-rite color matching software provide consistent top-notch printing quality.

Laminating

Our lamination processes preserve the quality of your packaging and provide a protective layer between the printed ink, your product, and your customers.

Coating

Specialty coatings can give packaging films additional properties to further suit your packaging needs. Heat seal, cold seal, and barrier coatings are all available.

Pouches

We offer pouches for a wide variety of applications with multiple configurations and sizes available. Our print and lamination capabilities allow us to manufacture stand-up pouches with sophisticated print and substrate configurations.

Bags

We have multiple side weld bagging machines capable of nearly any set-up. With our side weld wicketers, flat-bed machines, and bottom seal bag making machines with multiple attachments, you won’t find greater quality or capability anywhere else.

Slitting

We utilize a cantilevered slitting process with duplex slitter rewinders. Our modern, top of the line slitters provide fine taper control and lay-on roller pressure control for excellent roll uniformity.

INNO-LOK®

Our Hudson-Sharp INNO-LOK® machine applies a pre-zippered fastener transversely to your printed film to run on existing form-fill-seal equipment.

Other Services

Lab Testing

Our lab services allow us to ensure top quality performance for all our packaging products and research new, innovative solutions for our customers. Our lab team conducts extensive testing to validate materials and augment quality control. Quality testing includes:

– Barrier testing

– Heat seal testing

– Tensile strength testing

– Digital microscopy

– Friction testing

– Peel strength testing

– Seal strength testing

– Gas chromatography

– Spectrographic color analysis

Pre-Press

Our pre-press services include everything you need to prepare your designs for production. We offer full graphic design assistance and custom color development to make sure your packaging represents your vision and your needs.

We use the latest proofing and plate making technologies, including quick proofing and ink drawdowns to ensure the best quality production runs.